1. Overview / Opportunity

Every tonne of aluminum metal leaves behind four to five tonnes of bauxite residue — the highly alkaline by-product of alumina refining also known as red mud.

Over four billion tonnes have accumulated worldwide, with another 175 million tonnes produced every year.

Stored in either vast containment ponds or as dry stacked tailings, this waste is both an environmental burden and an untapped resource rich in iron, rare earth elements (REEs), scandium (Sc), gallium (Ga), and titanium (Ti).

GEOMEGA’s approach transforms red mud from waste to value, enabling a cleaner aluminum industry and creating new critical-metal supply chains.

2. Challenge / Industry Context

The aluminum sector faces a dual mandate: decarbonize operations and reduce legacy and fresh waste, while securing new sources of critical metals needed for clean energy.

Existing recovery methods are costly, chemical-intensive, or limited to single-metal extraction — leaving most of the value locked away.

GEOMEGA addresses this holistically, combining multi-metal recovery with real waste reduction.

3. GEOMEGA’s Approach

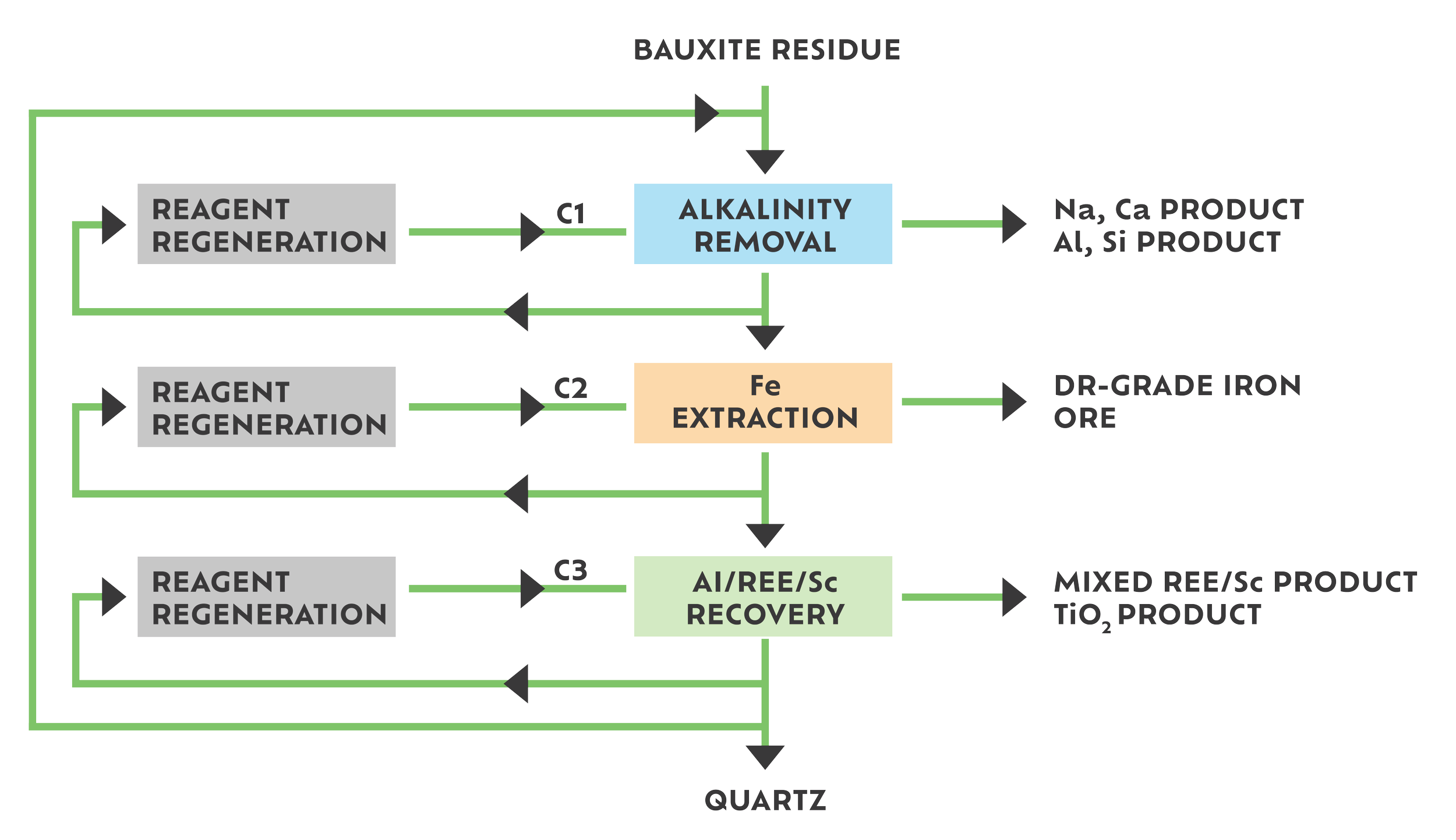

Through its closed-loop hydrometallurgical process, GEOMEGA integrates several core technologies including:

Iron Recovery & Valorization → produces high-purity DR-grade iron oxide

Reagent Recycling → regenerates reagents, minimizes effluents, and improves process economics

Critical Metal Extraction & Refining → extracts REEs, Sc, Ga, and Ti

A simplified process flowsheet illustrating the 3 circuits of the process is presented below:

The process could convert complex residues into multiple market-ready products (offtake streams) while cutting total waste volume by over 90 % when all 3 circuits are combined in a closed loop.

The process is scalable and designed for integration directly at refinery sites to work with both legacy residues or with fresh residues.

4. Validation & Proof of Concept

Following successful laboratory and pilot-scale validation, GEOMEGA’s subsidiary Innord Inc. has demonstrated efficient reagent recovery and high-purity product yields across multiple test campaigns.

Building on this proof, a Joint Development Agreement (JDA) and a Demonstration License with Rio Tinto mark the transition from proven pilot performance to pre-commercial demonstration — the final step before industrial deployment.

This collaboration establishes the world’s first integrated Bauxite Residue Valorization project in Saguenay, Quebec, setting a benchmark for circular innovation in the aluminum industry.

5. Value Creation

By offering offtake streams into well established global markets, the process offers up to 4 years payback to the alumina refinery. The economics of the project are driven by multiple metals, making it less susceptible to price fluctuations on any particular stream.

Each tonne of residue processed yields:

• DR-grade iron oxide for low-carbon steelmaking

• Nd, Pr, Dy, Tb oxides to make magnets for EVs and wind turbines

• Scandium (Sc) for Al-Sc alloys and fuel cells

• Gallium (Ga) for semiconductors

• Titanium (TiO₂) for pigments and aerospace

• Caustic soda (NaOH) an important reagent in alumina production and many other industries

• Smelter grade alumina for aluminum production

• CaO for the cement industry

• Silica-gel (SiO2) for many industrial uses

Market context

• DR-grade iron ore market US $31 B (2022), 8.6 % CAGR

• Sc market: >US $ 500 M (2024), 8.7% CAGR

• Gallium market: >US $350 M (2024)

• TiO2 market: >US $25 B (2023)

• Caustic soda market: >US $50 B (2024)

• Global aluminum market: >US $230 B

By recovering these materials, refineries turn liabilities into long-term assets - shifting from waste management to resource creation.

6. Environmental & Social Impact

• Over 90% reduction in residue volume

• No or limited secondary waste — closed water and reagent loops

• Reduced risk of dam failure and groundwater contamination

• Supports land rehabilitation and ESG compliance

From red mud to renewable metals - proof that circular mining is not only possible but profitable.

7. Partnership & Scalability

Licensing and Build-Own-Operate (BOO) models enable rapid adoption by refineries worldwide.

Work is ongoing for multiple clients ranging from bench to pre-commercial demonstration scale.

The technology could be deployed globally with commercial scale plants processing millions of tonnes per year based on the client’s size of legacy tailings and annual production of fresh bauxite residues.

Let’s reclaim the future of aluminum together

Contact Kiril Mugerman, President & CEO, to discuss partnerships and to organize testwork on your bauxite residues using our technology..

kmugerman@geomega.ca

+1 514-223-1449 ext. 3